Temperature Elements Thermocouples / RTD Assembles:

RESISTANCE TEMPERATURE DETECTOR (RTD)

- It employs high purity electrical resistance wire, non inductively wound on ceramic or glass base.

- When RTD element is subjected to heat, it changes its electrical resistance value, corresponding to variation in temperature and its thermal coefficient (8) (Alpha).

- The temperature resistance characteristics have an established pattern for different resistance elements, like Copper, Nickel, Platinum etc.

- Most commonly used resistance element in Platinum known as Pt 100 (100 ohms at 0°C) Temperature resistance characteristics conform to DIN 43760/ IEC 751 / BSS 1904/ JIS C 1604 standards.

| Temperature°C |

Tolerance

IEC 751:1983 (BS 1904:1984, DIN3760:1980) |

| Class A |

Class B |

| ±°C |

±0hms |

±°C |

±°0hms |

| -200 |

0.55 |

0.24 |

1.3 |

0.56 |

| -100 |

0.35 |

0.14 |

0.8 |

0.32 |

| 0 |

0.15 |

0.06 |

0.3 |

0.12 |

| 100 |

0.35 |

0.13 |

0.8 |

0.30 |

| 200 |

0.55 |

0.20 |

1.3 |

0.48 |

| 300 |

0.75 |

0.27 |

1.8 |

0.64 |

| 400 |

0.95 |

0.33 |

2.3 |

0.79 |

| 500 |

1.15 |

0.38 |

2.8 |

0.93 |

| 600 |

1.35 |

0.43 |

3.3 |

1.06 |

| 650 |

1.45 |

0.46 |

3.6 |

1.13 |

| 700 |

-- |

-- |

3.8 |

1.17 |

| 800 |

-- |

-- |

4.3 |

1.28 |

| 850 |

-- |

-- |

4.6 |

1.34 |

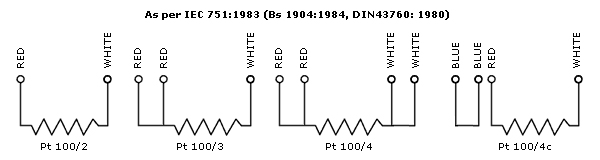

TYPICAL CONNECTION SCHEMATICS FOR 2, 3 & 4 WIRE LEAD

CONFIGURATION FOR RESISTANCE THERMOMETER DETECTORS

|

|